Product Details

Product Introduction

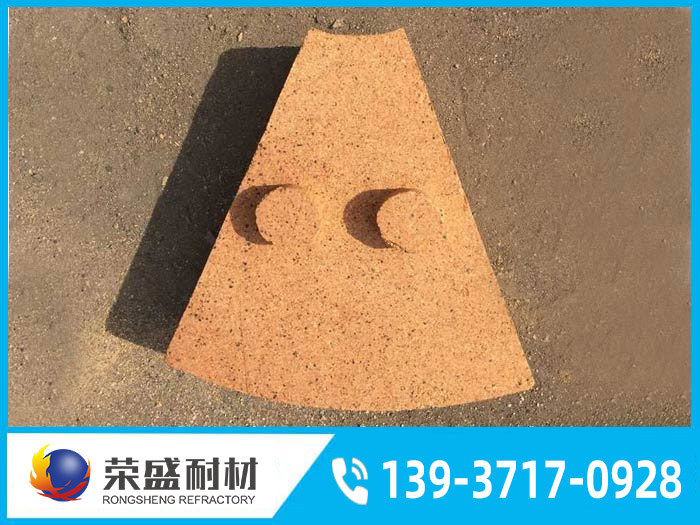

Rongsheng’s premium clay refractory bricks represent a distinguished selection of refractory products, expertly engineered using high-quality soft and hard clay clinkers combined in a precise particle size distribution and bonded with refractory clay. With Al2O3 content ranging from 30% to 48%, these bricks undergo a rigorous high-temperature sintering process at 1300 to 1400°C, providing exceptional resistance to rapid thermal changes while maintaining consistent thermal characteristics. This mild acidic refractory material is primarily designed to withstand the aggressive nature of acidic slags and gases, while also offering a degree of resistance to alkaline substances. Rongsheng clay refractory bricks find extensive use in numerous high-temperature applications, including thermal boilers, glass kilns, cement kilns, gasification furnaces, and blast furnaces, ensuring operational efficiency and structural stability. The broad range of product classifications features fan-shaped clay bricks and various specialized designs tailored to fulfill the specific requirements of diverse applications. Through ongoing technical innovation and state-of-the-art manufacturing techniques, these products comply with international standards for quality and durability, establishing them as the preferred option for clients both locally and globally in high-temperature situations.

Advantages and features

1. Our products are crafted from premium raw materials, ensuring exceptional resistance to sudden temperature fluctuations and consistent thermal stability; 2. Featuring an aluminum oxide (Al2O3) content between 30% and 48%, they provide excellent thermal efficiency and resistance to corrosion; 3. Subjected to high-temperature sintering processes exceeding 1300 to 1400℃, our products demonstrate impressive durability and long-lasting strength; 4. Various configurations are designed to meet the specific challenges of distinct kiln designs and specialized operational settings; 5. Adhering to international quality standards ensures broad applicability for a diverse range of clients worldwide.

Application Scenario

1. Thermal applications: applicable in thermal boilers and gas generators; 2. Metallurgical industry: suitable for use in blast furnaces, cement kilns, glass kilns, and others; 3. Custom-shaped bricks can be designed upon request to meet the distinct needs of various kilns.